Technical 6: Quality & Conformance

Churchill ceramics are continuously tested and quality checked, from the stage of raw materials, throughout the manufacturing process to the fired piece.

High Quality

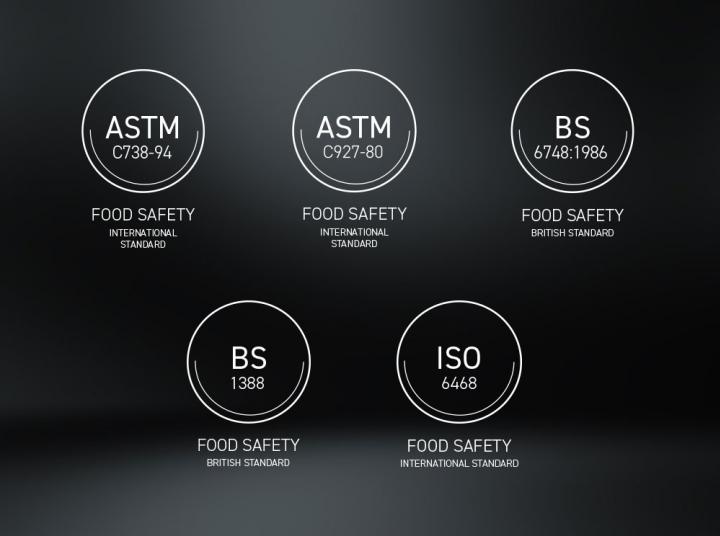

We test our products to 13 British, European and global standards, ensuring that our products perform even in the busiest professional kitchens.

These tests include dishwasher testing that simulates 5000 dishwasher cycles, edge chip testing to ensure impact resistance and the vitrification of our performance clay bodies. We also test the resilience of our glaze to scratching and thermal shock.

We test daily in our inhouse UKAS accredited lab:

1. Our performance materials - China Clay, Alumina, Ball Clay, Fillers and Fluxes

2. Engineered Shape and Form - Size, Shape and Stackability and Shape and Consistency.

3. Vitrification - Water Absorption

4. Glazing - Dishwasher, Glazing and Thermal Stability

5. Quality and Conformance - Edge Chip Resistance

We test metal release to five different British, European and global quality standards, this ensures our products are safe for contact with food. When we innovate with coloured tableware, our new collections always pass the same high standards of food safety as our white portfolio.